VINTEKO has a wealth of professional technology and knowledge in the field of press assembly, and continues to export high-end press assembly products to the world. "To improve the ecological environment as its own responsibility, to practice the road of sustainable development" is as early as 2013, the company vision released at the beginning of the company's establishment, the vision gives us the direction, which makes the company can always be on the right development line. We have achieved a lot by providing efficient products that allow us to be part of the solution to environmental problems, but we still have a long way to go.

"Continuously improve product quality, improve service level, constantly pursue excellence, continuous innovation" is our original intention and commitment. With the rapid development of aerospace and new energy vehicles, the need for lightweight materials, recyclable products and sustainable assembly processes is becoming more and more urgent, and these needs are related to loose connections. The BSU26 is the adaptation solution to be launched in 2025, and this innovative dual servo riveting system for riveting nuts and riveting bolts takes us one step closer to our vision of "improving the ecological environment". Riveted nuts and riveted bolts are ideal for "lightweight materials, recyclable products and sustainable assembly", and the BSU26 enables this assembly to achieve a high degree of automation, while ensuring the reliability of the process.

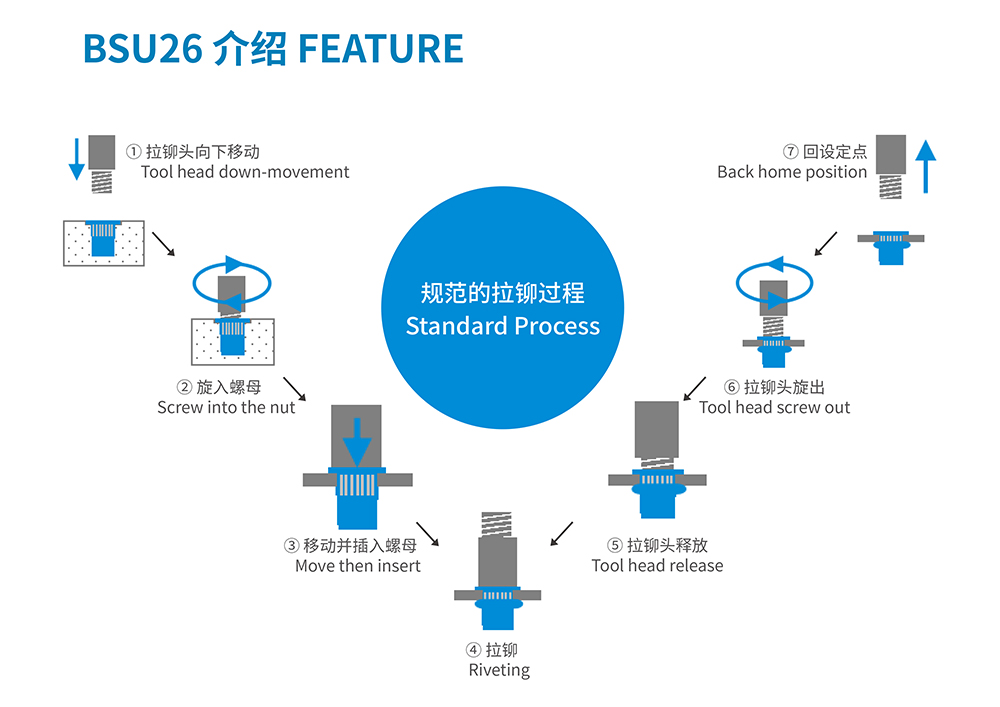

BSU26 Features :

· May be the first double servo automatic rivet system

· Original hexagonal nut quick positioning function, further improving the rivet beat

· can automatically detect the blind nut qualified

· Rivet rod using standard parts, greatly reduces the cost of spare parts

· 10 seconds quick replacement of rivet rod, without any auxiliary tools

· extremely compact setup Maintenance-free, maintenance-free

· Compatible with all kinds of riveting nuts and nail feeding systems

BSU26 adopts the method of simultaneous monitoring and measurement of pulling force and pulling distance, which is used for automatic assembly of riveted nuts and riveted bolts. It has the characteristics of strong versatility, high performance and fast rhythm. It can meet the economic needs well, and will be widely used in automobile body, chassis, axle, battery pack, bumper, seat belt, airbag, aircraft, motorcycle, public transportation, special vehicles, ships and other manufacturing and assembly fields.