In the fast-paced world of foodservice and hospitality, commercial blenders are indispensable tools for creating everything from smoothies to soups. As consumer demands for high-quality, efficient blending solutions grow, the need for a specialized production process becomes crucial. At Finern Automation, we offer customized automated production lines designed specifically for the assembly of commercial blenders, ensuring that manufacturers can deliver exceptional products that meet the rigors of professional use.

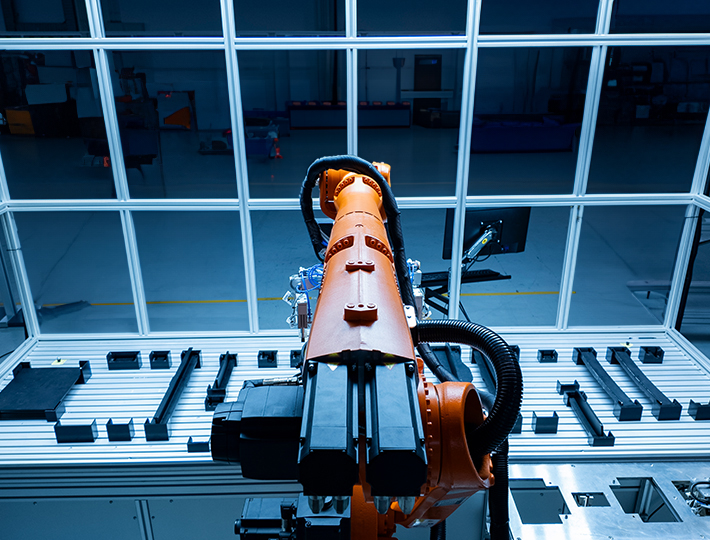

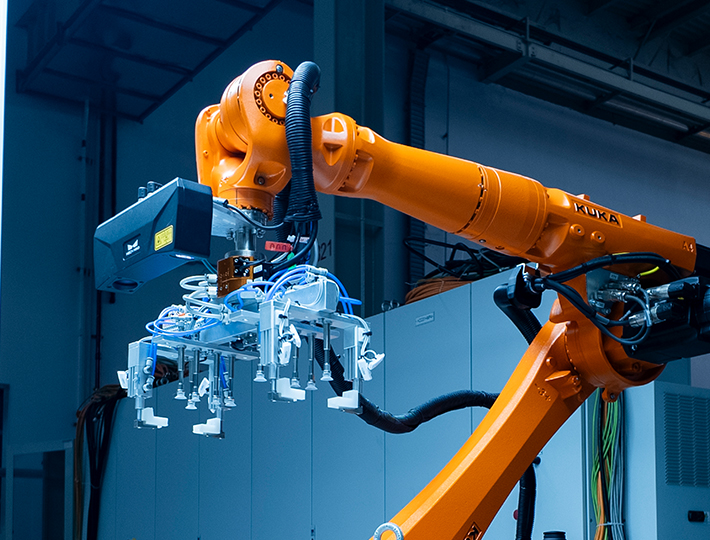

Our state-of-the-art assembly line is tailored to accommodate various blender designs and configurations, allowing for flexibility in production. By leveraging advanced robotics and automation technology, we streamline the integration of key components, including powerful motors, precision blades, and user-friendly controls. This efficient assembly process not only reduces production time but also ensures that each unit is built to withstand the demands of daily commercial use.

Quality assurance is paramount in our assembly process. Each commercial blender undergoes comprehensive testing to verify performance, durability, and safety. Our automated testing systems assess critical metrics such as blending efficiency, noise levels, and thermal performance, ensuring that every unit meets the high standards required in the foodservice industry.

By implementing a customized automated production line for commercial blenders, we empower manufacturers to produce reliable and innovative blending solutions that enhance culinary creativity. Our commitment to excellence and efficiency in production helps drive advancements in food preparation technology, positioning our partners for success in a competitive marketplace.